I. Introduction

In our increasingly interconnected world, the ripple effects of seemingly distant events can be felt almost instantaneously across continents. A political tremor in one nation, a localized conflict, or even a protest can send shockwaves through global markets, disrupting the intricate dance of supply and demand. This is particularly true for supply chains, the unsung heroes that ensure everything from your morning coffee to your smartphone reaches you. Geopolitical instability, especially in dynamic regions like Africa, is proving to be a significant disruptor, demanding not just resilience but also innovative solutions in logistics, operations, transportation, and regulatory frameworks. Who knew a butterfly flapping its wings in one continent could cause a supply chain hurricane on another? It’s less about the butterfly and more about the interconnectedness we’ve built, making every political gust a potential gale for global trade.

2025 Geopolitical Storm: Tariff-Proofing Your Supply Chain

II. The Kenyan and African Context: A Microcosm of Macro Challenges

To truly grasp the magnitude of these disruptions, one needs only to look at the recent trending topics emanating from Kenya and across the African continent. From widespread protests against proposed finance bills in Kenya to ongoing regional conflicts, such as the persistent tensions between the Democratic Republic of Congo and Rwanda, these events are not isolated incidents. They are potent reminders of how local sociopolitical dynamics can rapidly escalate into significant impediments for regional and international trade.

Consider the protests in Kenya. While primarily domestic in nature, their impact on urban centers and key transportation arteries can lead to immediate bottlenecks. Goods destined for local markets or for export can be delayed, perishable items can spoil, and businesses face increased operational costs due to rerouting or heightened security measures. Similarly, conflicts in the Eastern DRC, while geographically contained, have profound implications for cross-border trade, particularly for minerals and other raw materials that feed into global supply chains. Roads become impassable, borders are intermittently closed, and the risk premium for transporting goods through these regions skyrockets. This translates into increased lead times, higher freight costs, and a general air of uncertainty that makes long-term planning a logistical nightmare. The seemingly localized issues in Africa serve as a stark, real-time case study of how macro-level geopolitical shifts manifest as tangible, costly challenges for the supply chain, forcing businesses to adapt or face significant losses.

III. Supply Chain: The Unsung Hero on the Front Lines

In the face of such geopolitical turbulence, the supply chain emerges as the unsung hero, often bearing the brunt of these external shocks. The immediate impact is felt in sourcing and procurement. When key regions are destabilized, the availability of raw materials or finished goods can become erratic. This forces companies to scramble for alternative suppliers, often at higher costs and with longer lead times, directly impacting production schedules and profitability. Maintaining optimal inventory levels becomes a high-stakes gamble; too much, and you risk obsolescence or increased holding costs; too little, and you face stockouts and missed sales opportunities. The traditional ‘just-in-time’ model, while efficient in stable environments, can become a ‘just-in-trouble’ scenario when geopolitical winds shift unexpectedly. This necessitates a fundamental re-evaluation of risk assessment strategies, moving beyond mere economic indicators to incorporate a deeper understanding of political landscapes and social stability. Diversifying supply bases, even if it means slightly higher initial costs, becomes a critical resilience strategy, ensuring that the disruption in one region doesn’t bring the entire operation to a grinding halt. The supply chain, therefore, is not just about moving goods; it’s about foresight, adaptability, and an almost clairvoyant ability to anticipate the next global hiccup.

IV. Logistics & Transportation: Navigating the Minefield

If the supply chain is the circulatory system of global commerce, then logistics and transportation are its arteries and veins. When geopolitical instability strikes, these vital pathways can quickly become minefields. Freight forwarding, warehousing, and distribution networks are immediately impacted. Road closures due to protests, blockades at borders, or the outright cessation of air and sea routes in conflict zones can bring the movement of goods to a standstill. This isn’t just an inconvenience; it translates directly into increased costs – higher insurance premiums, demurrage charges for delayed shipments, and the expense of rerouting through longer, less efficient pathways.

Consider the complexities of transporting goods across East Africa, where political unrest in one country can force trucks to take circuitous routes, adding days, even weeks, to transit times. This not only inflates fuel costs but also ties up valuable assets and delays delivery to end-consumers. For air and sea freight, the risks are equally pronounced, with certain regions becoming no-go zones, leading to significant diversions and capacity constraints. The silver lining, if there is one, lies in the increasing adoption of technology. Real-time tracking systems, predictive analytics for route optimization, and even drone technology for last-mile delivery in challenging terrains are becoming indispensable tools. However, even the most sophisticated technology can only mitigate, not eliminate, the fundamental challenges posed by a volatile geopolitical landscape. Turns out, ‘smooth sailing’ is less about the sea and more about the political climate – a lesson learned, often painfully, by those in the logistics trenches.

V. Operations: Adapting to the New Normal

Beyond the movement of goods, geopolitical instability directly impacts the operational heart of businesses: manufacturing and production. When supply chains falter, the availability of critical components and raw materials becomes unpredictable, leading to production delays, reduced output, and even factory shutdowns. This forces operations teams to become masters of improvisation, constantly adapting to fluctuating inputs and market demands. The traditional emphasis on lean manufacturing, while valuable for efficiency, can expose vulnerabilities when the flow of materials is interrupted.

Agility becomes paramount. Companies need to cultivate flexible production lines that can quickly pivot to alternative materials or adjust output based on available resources. This might involve investing in multi-purpose machinery, cross-training staff, or even decentralizing production to minimize the impact of localized disruptions. Business continuity planning, once a theoretical exercise, transforms into a critical operational imperative. This includes developing robust disaster recovery strategies, establishing emergency communication protocols, and regularly stress-testing the entire operational framework against various geopolitical scenarios. The goal is not just to survive the storm, but to emerge stronger, with operations that are resilient enough to absorb shocks and continue delivering value, even when the world outside seems to be in disarray. It’s about building a factory that can dance, not just march, to the unpredictable rhythm of global events.

VI. Regulations: The Shifting Sands of Compliance

In the turbulent waters of geopolitical instability, regulations become less of a stable bedrock and more of a shifting sand dune. Trade policies can change overnight, sanctions can be imposed with little warning, and customs procedures can become labyrinthine, all in response to evolving political landscapes. For businesses operating across borders, this creates a compliance nightmare. What was permissible yesterday might be illegal today, and navigating this ever-changing regulatory environment requires constant vigilance and specialized expertise.

Consider the complexities introduced by new tariffs, import/export restrictions, or even changes in the interpretation of existing laws in response to political pressures. Companies must invest heavily in legal and compliance teams that are not only well-versed in international trade law but also possess a keen understanding of geopolitical dynamics. The ability to anticipate regulatory shifts, assess their potential impact, and proactively adjust business practices becomes a significant competitive advantage. Furthermore, the lack of harmonized regulations across different jurisdictions, exacerbated by political tensions, can create significant friction points in the supply chain. This underscores the critical role of international cooperation and multilateral agreements in fostering a more predictable and stable global trading environment. Without it, businesses are left to contend with a patchwork of rules that can stifle trade and add layers of unnecessary complexity. It’s a constant game of regulatory whack-a-mole, where the rules keep changing, and the stakes are always high.

VII. The Path Forward: Resilience, Innovation, and Collaboration

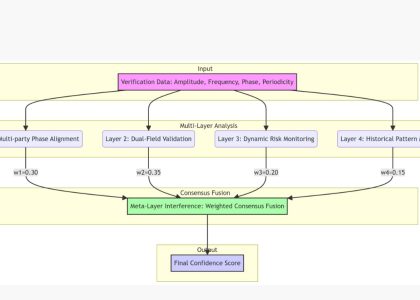

While the challenges posed by geopolitical instability are formidable, they also serve as a powerful catalyst for innovation and strategic evolution within supply chains. The path forward is paved with resilience, driven by technological advancements, and strengthened by collaborative efforts. Investing in supply chain visibility is no longer a luxury but a necessity. This means leveraging advanced analytics, AI, and blockchain to gain real-time insights into every node of the supply network, from raw material sourcing to final delivery. Predictive analytics can help anticipate potential disruptions, allowing businesses to proactively reroute shipments, adjust production schedules, or secure alternative suppliers before a crisis fully unfolds.

Embracing digitalization and automation is another critical step. Automated warehousing, robotic process automation (RPA) for administrative tasks, and digital platforms for customs clearance can significantly reduce human error, increase efficiency, and provide greater flexibility in responding to unforeseen events. Furthermore, fostering public-private partnerships and regional collaborations is paramount. Governments, international organizations, and private sector entities must work together to create more stable trade corridors, harmonize regulations, and invest in critical infrastructure that can withstand political shocks. The human element, too, cannot be overlooked. Training and empowering supply chain professionals with the skills to navigate complex geopolitical landscapes, understand diverse regulatory frameworks, and make agile decisions under pressure is crucial. It’s about building a workforce that is not just efficient but also adaptable, insightful, and capable of strategic thinking. In essence, the future of supply chains isn’t just about moving goods; it’s about building intelligent, interconnected, and human-centric networks that can weather any storm with a healthy dose of strategic wit and unwavering determination.

VIII. Conclusion

In conclusion, geopolitical instability is not merely a headline; it is a tangible force reshaping global supply chains. From the bustling markets of Kenya to the complex trade routes spanning continents, the impact of protests, conflicts, and shifting political alliances reverberates through every aspect of logistics, operations, transportation, and regulatory compliance. This challenge, however, is also a powerful impetus for change. It compels businesses to move beyond traditional models of efficiency and embrace a new paradigm centered on resilience, innovation, and collaboration. The future of supply chains isn’t just about getting goods from point A to point B; it’s about building robust, adaptable networks that can anticipate, absorb, and even thrive amidst uncertainty. It demands foresight, technological prowess, and a healthy dose of strategic wit to navigate the ever-changing global landscape. After all, in a world where a butterfly can cause a hurricane, a well-prepared supply chain can be the calm in the storm.

What are your thoughts on –

2025 Geopolitical Storm: Tariff-Proofing Your Supply Chain?

Be part of the Cool Vibes Supply Chain Coded—subscribe on YouTube!

Join Now